The new built-in adjustable four-function valve structure with adjustable automatic emptying / pressure relief, automatic oil replenishment and limit is sensitive, reliable and superior in performance. The application of the limit oil replenishment mechanism not only guarantees the fullness of the hydraulic oil in the hydraulic chamber, but also avoids excessive oil replenishment and prevents hydraulic shock, thereby balancing the forces on both sides of the diaphragm and increasing the service life of the diaphragm. The combination of a valve and a safety valve, the air release valve can keep the hydraulic oil in the hydraulic chamber pure liquid and improve the volumetric efficiency; the safety valve is automatically opened for the obstruction of overpressure on the process pipeline to protect the safety of the pump and pipeline.

The asymmetric membrane cavity structure keeps the forces on both sides of the diaphragm always balanced, plus the application of the upper limit oil replenishment mechanism. The diaphragm metering pump has self-priming performance, the diaphragm has a long service life, and is suitable for conveying suspended solids.

The cylinder body and cylinder head are made of forged parts to avoid leakage inside the casting due to high pressure. The flow-through parts of the corrosion-resistant metering pump are made of engineering plastics such as polytetrafluoroethylene and polyvinylidene fluoride. And strong corrosive media such as hydrochloric acid.

Use the space of the pump head bracket as the oil storage tank to avoid the lack of oil and refill air, and eliminate the hidden danger of unsafe.

The piston ring seal is used instead of the packing seal, which has automatic wear compensation, extremely low friction coefficient, and low power consumption. It changes from wearing parts to conventional parts, with a service life of more than 3 years, avoiding frequent replacement of packing.

It can be equipped with pressure sensitive diaphragm rupture alarm device, which is composed of source alarm, pressure sensor and YB alarm. The two diaphragms are vacuumed automatically after operation, no vacuum is required, and the middle of the two diaphragms is always in a vacuum state. It can send out alarm signals (local display or remote alarm), ensuring the safety of operators and system processes.

It adopts variable eccentric sliding shaft type stroke adjustment mechanism, which is flexible, accurate and reliable. It can adjust the flow length by 0 ~ 100% linear stepless adjustment of stroke length, and the measurement accuracy E≤1%.

The micro-hydraulic diaphragm metering pump uses the internal circulation hydraulic circuit technology to successfully solve the problem of expelling the gas in the membrane cavity, air passage, oil passage and hydraulic cavity. The performance is reliable, the measurement accuracy is high, and the service life of the diaphragm reaches more than 30,000 hours.

Ball valve, wing valve, mushroom valve and other types of check valves are available. Linear seal, good sealing performance and long service life.

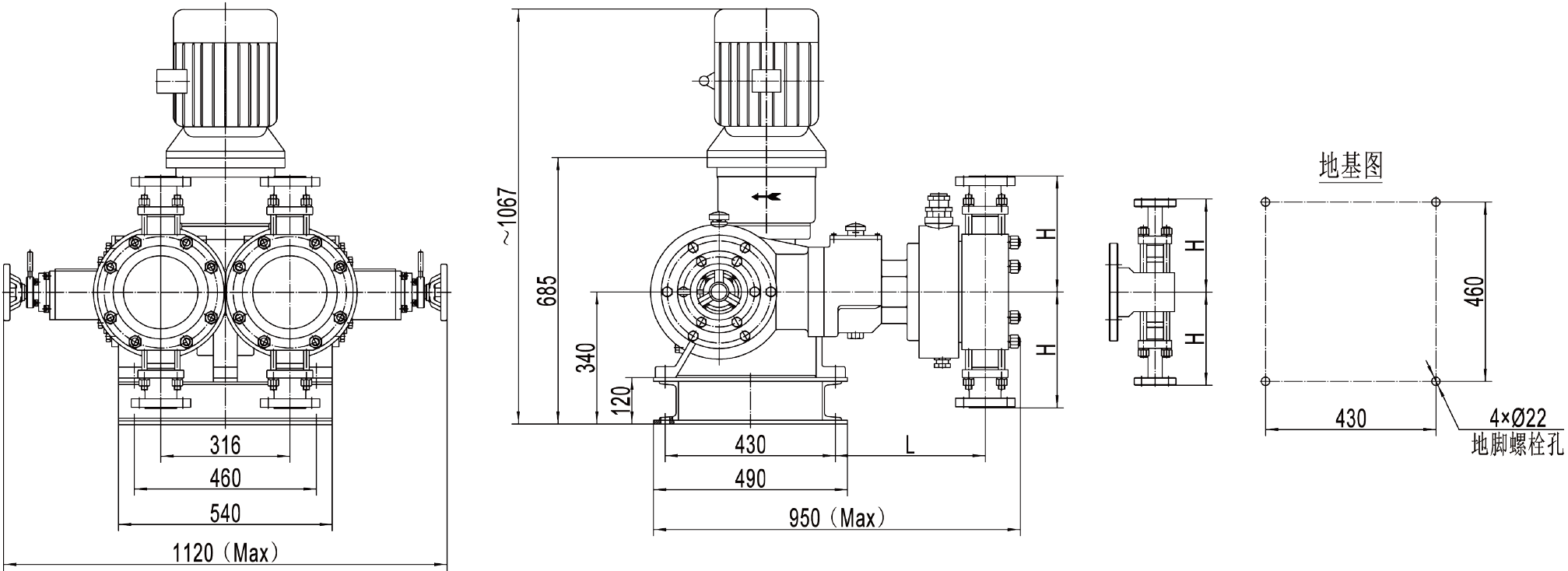

The combination of double, triple and more multiple pumps can be used to smooth pressure pulses and flow unevenness, and can also be used as a proportional pump.

Various materials such as 304, 304L, 316, 316L, Monel, Hastelloy B, Hastelloy C, 20 alloy, 904L, duplex steel, PVC, PP, PE, PTFE, PVDF, etc.

A variety of flow adjustment methods such as manual, electric and variable frequency speed regulation are suitable for various control requirements of the system.

The column (living) plug is connected to the crosshead. The crosshead drives the column (living) plug to perform a linear reciprocating motion. It is transformed into a periodic elastic deformation of the diaphragm by the transmission of hydraulic oil. The suction and discharge are achieved by the opening and closing of the check valve. Purpose of the liquid.